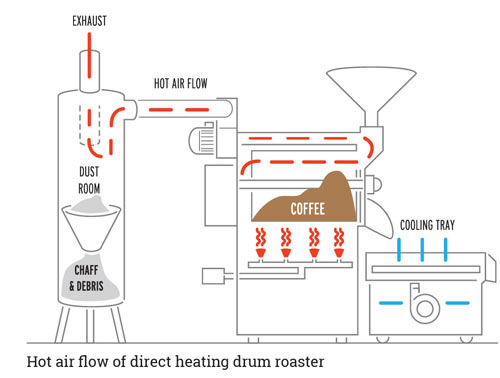

Direct heating system

Direct heating system roasters use LPG, natural gas or electricity for heating.

The fire both heats up the drum and the air inside the drum. Hot air is absorbed from the drum by means of fans, and passes through the flowing beans.

Green beans inside the drum touch the inner wall of the drum and are roasted by heat which is transferred by conduction method. Specially designed stirring vanes inside the drum provide the beans with homogenous heat transfer.

Roasting cycyle inside the drum is checked by sampling spoon, sight glass and heat control system.

Coffee beans which are roasted at desired quality are discharged into the cooling unit either by the operator or automatically, and get cool very quickly.

The fan inside the roaster absorbs aromatic gases, steam, and chaff as well as hot air.

The chaff, absorbed by the fan with hot air, moves to the dust room and captured there while the hot air is discharged out of the building through the chimney.

Tiny dust particles and aromatic gases, remaining in hot air, are reburned by an afterburner; and the hot air, conditioned to comply with environmental regulations, is discharged off the building.

Double-walled roasting drums are the best, where there is some space between inner and outer layers. While the outer drum layer directly contacts with flame, the inner drum layer stays relatively a bit cooler.

These roasters reduce conduction heat transfer and avoid beans from being overroasted, escaping outside, and exposing directly to heat.

Advantages

Drum warms up quickly. Direct heating roasters consume low energy and are easy to use. They provide cleaner roasting ambient since this method constantly absorbs and uses clean air.

Hot air supports the conduction transfer during the first few minutes of roasting and makes the drum store the heat effectively.

Installation is cost-efficient.

Disadvantages

Over-heating of the metal drum may cause burnt spots on bean’s surface.

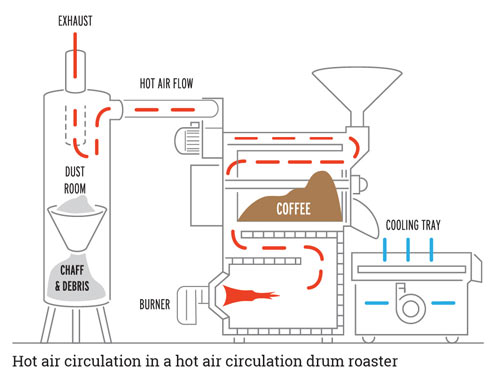

Hot air circulation system

Air is heated inside the roaster or in a combustion chamber outside the roaster.

Drum is not in direct contact with flames, and there is minor risk of burnt surfaces on the bean. Rest of the process is just the same as direct heating system.

Advantages

It takes longer to heat the roaster and drum. Power consumption is reduced if several batches are roasted every day. It is easy to use. It provides cleaner roasting ambient since the system constantly absorbs and uses clean air. The risk of burnt coffee beans is lower relatively to direct heating drum roasters.

Disadvantages

Power consumption is high if only a few batches are roasted daily.

Installation is high-cost.

Coffee roasters by their heat source

Various heat sources can be used in coffee roasters depending on several reasons such as :

• Official permissions’ limitations regarding the area where the facility is established,

• Environmental rules and regulations of the country,

• Fuel or power costs of the country where the facility is established,

• Restrictions regarding the physical conditions of the facility (no chimney, etc.),

• Inefficiency of some fuels’ low calorific properties to meet the high heat requirements of high capacity roasters.