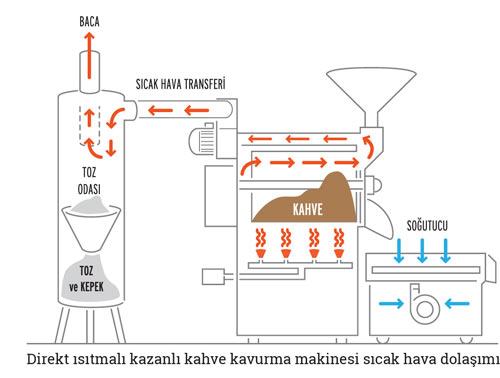

Direct heat transfer coffee roasters

The heaters of direct heat transfer coffee roasters can be heated by liquid gas, natural gas or electricity. In gas heaters, the fire heats both the boiler and the air drawn into the boiler. The hot air is sucked through the boiler with the help of a fan and passes between the beans rotating in the boiler. The green coffee in the boiler comes into contact with the inner wall of the hot boiler and is roasted thanks to the heat it receives by touch (conduction). Special mixing paddles in the boiler ensure homogeneous transfer of heat between the coffee beans. The roasting of the coffee in the boiler is controlled by sample spoon, sample glass and temperature control systems. When the roasting process is completed, the coffee beans roasted to the desired quality are taken to the cooling section by operator command or automatic control systems and cooled very quickly.

In this type of machine, the fan sucks in aromatic gases, water vapor and the outer shell of the coffee (bran) in addition to the hot air in the boiler. The bran, which is carried by the fan with hot air, comes to the powder room and is kept there. In accordance with environmental norms in some countries, the small dust and aromatic gases remaining in the hot air are destroyed by an afterburner, and the hot air, which has been brought into compliance with environmental norms, is discharged outside the building. The best boiler roasters use double-deck boilers. In this type of boilers, there is a certain space between both floors. In double-deck boilers, while the outer boiler is in direct contact with the fire, the inner boiler remains cooler than the outer one. Such roasters reduce the heat transfer through touch (conduction) and prevent the core from over-roasting, escaping to the outside and being directly exposed to heat

AdvantagesMachine and boiler heat up in a short time. Fuel consumption is low and easy to use. A cleaner roasting environment is provided as fresh air is continuously sucked into the system, heating and utilized. Hot air promotes conduction transfer during the first few minutes of the roasting process, making the boiler an effective heat store. Installation costs are lower.DisadvantagesOverheating of the metal boiler can cause burn spots on the core surface

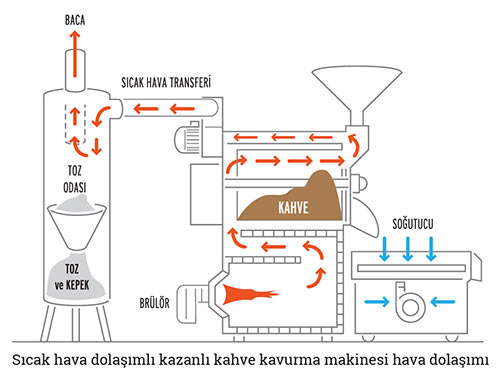

Hot air circulation machines

In hot air circulation boiler coffee roasters, hot air is generated within the machine or in a combustion chamber outside the machine. In this design, the boiler has no direct contact with fire. The risk of burning the surface of the bean is low. Other than that, the whole working system is just like a direct transfer boiler coffee roaster

AdvantagesThe machine and the boiler heat up later. Fuel consumption is reduced if coffee is roasted many times a day. Easy to use. A cleaner roasting environment is provided as fresh air is constantly sucked into the system, heated and used. There is less risk of burning on the coffee surface than with a direct heat transfer boiler roaster.DisadvantagesFuel consumption is high if roasting only a few times a day. Installation costs are high

Coffee roasters by heat source

Different heat sources can be used in coffee roasters. Among the various reasons for this: – Reasons related to the official permits to be obtained for the area where the coffee will be roasted, – Environmental norms and regulations in the country of installation, – Fuel costs in the country where the business is located, – Limitations arising from the physical conditions of the workplace (no chimney in the workplace, etc.) – Conditions such as the inability to provide the necessary heating with some heat sources in high capacity coffee roasters.